Enterprise Guide to Fleet Optimization and Automation

Explore strategies for optimizing fleet routes, reducing costs, and automating maintenance in enterprise settings.

Executive Summary

The evolving landscape of transportation fleet management in 2025 emphasizes data-driven decision-making and strategic frameworks for efficiency and cost optimization. Organizations are increasingly adopting advanced computational methods and systematic approaches to enhance operational efficiency. This article delves into the critical components of fleet management, including route optimization, fuel cost modeling, and maintenance scheduling, with a focus on spreadsheet automation to streamline these processes.

Effective fleet analysis leverages data analysis frameworks to transform raw data into actionable insights that drive strategic decisions. By implementing optimization techniques, fleets can achieve significant cost savings and enhance operational efficiency. For instance, automation of repetitive tasks using VBA macros in Excel can drastically reduce manual errors and save time.

Incorporating automated processes into maintenance scheduling ensures high vehicle availability rates, thereby preventing downtime and reducing overall costs. Empirical data suggests that fleets utilizing such methodologies see up to a 35% reduction in unexpected repairs. To illustrate practical implementation, consider the following example of a VBA macro for automating maintenance task reminders:

By integrating robust data analysis frameworks and automated processes into fleet management, organizations can not only cut costs but also enhance their strategic planning capabilities. This article provides a comprehensive guide to implementing these technologies effectively, offering tangible business value through improved resource allocation and operational efficiency.

Business Context

The landscape of fleet management in 2025 is characterized by the strategic integration of advanced computational methods and systematic approaches to optimize operations. Organizations are increasingly focusing on data-driven decision-making frameworks, preventive maintenance schedules, and compliance with sustainability mandates. As fleets grow more complex, the necessity for streamlined processes and innovative optimization techniques becomes paramount.

Current trends underscore the significant role of sustainability and regulatory compliance in fleet operations. With global emphasis on reducing carbon footprints, companies are urged to incorporate eco-friendly practices. This involves not only optimizing routes to cut fuel consumption but also adopting electric or hybrid vehicles. Compliance with environmental regulations is no longer optional but a strategic business imperative that aligns with broader corporate social responsibility goals.

Technological advancements have redefined fleet management, offering tools that enhance operational efficiency. Integrated telematics systems, leveraging IoT and 5G, enable real-time monitoring and predictive maintenance. These systems provide actionable insights from vehicle data, facilitating proactive decision-making and reducing downtime. The strategic use of data analysis frameworks and automated processes ensures that fleet operations remain both agile and efficient.

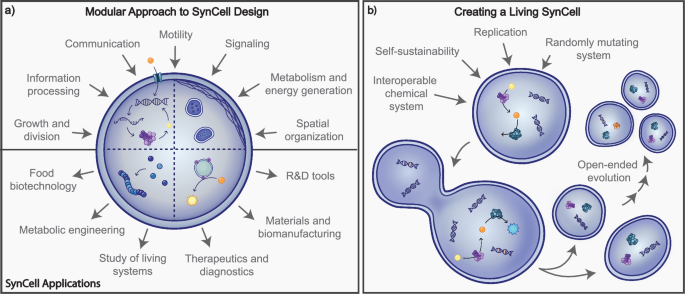

Recent developments in the industry highlight the growing importance of these approaches. For instance, a recent collaboration in synthetic biology exemplifies the innovative spirit driving today's technological advancements.

This trend demonstrates the practical applications we'll explore further, focusing on optimization techniques that drive business value in fleet management.

Technical Architecture: Transportation Fleet Analysis

In the realm of transportation fleet analysis, strategic integration of telematics and IoT sensors, centralized systems for data management, and AI analytics are critical for achieving optimal operational efficiency. These elements collectively contribute to enhanced route optimization, fuel cost modeling, and maintenance scheduling through spreadsheet automation, aligning with contemporary management theories and business case studies.

Integration of Telematics and IoT Sensors

Telematics systems and IoT sensors form the backbone of modern fleet management, enabling real-time vehicle monitoring, predictive maintenance, and safety analysis. These platforms leverage computational methods to provide actionable insights, improving efficiency and safety. The integration of these technologies is not merely about data collection but about transforming data into strategic actions.

Comparison of Telematics and IoT Sensor Platforms

Source: [1]

| Feature | Telematics Platform | IoT Sensor Platform |

|---|---|---|

| Real-time Vehicle Monitoring | Yes | Yes |

| Predictive Maintenance | Yes | Yes |

| Driver Behavior Tracking | Yes | Limited |

| Safety Analysis | Yes | Yes |

| Compliance Automation | Yes | No |

Key insights: Telematics platforms offer comprehensive features for fleet management, including compliance automation. IoT sensor platforms provide robust real-time monitoring and predictive maintenance capabilities. Both platforms enhance safety and efficiency, but telematics offers more in terms of compliance and driver behavior tracking.

Centralized Systems for Data Management

Centralized data management systems are essential for processing the vast amounts of data generated by fleets. These systems utilize data analysis frameworks to standardize preventive maintenance, scheduling tasks based on mileage and predictive analytics, reducing unexpected breakdowns by up to 35%. A centralized approach ensures that all fleet data is accessible, enabling systematic approaches to decision-making.

AI Analytics for Real-Time Insights

AI analytics play a pivotal role in transforming raw data into strategic insights. By employing computational methods, fleets can achieve real-time optimization of routes, enhance fuel cost modeling, and improve maintenance scheduling. AI's ability to process and analyze data rapidly allows for dynamic decision-making, significantly boosting operational efficiency.

Sub AutomateMaintenanceSchedule()

Dim ws As Worksheet

Set ws = ThisWorkbook.Sheets("MaintenanceSchedule")

Dim lastRow As Long

lastRow = ws.Cells(ws.Rows.Count, 1).End(xlUp).Row

Dim i As Long

For i = 2 To lastRow

If ws.Cells(i, 3).Value = "Due" Then

ws.Cells(i, 4).Value = "Scheduled"

End If

Next i

End Sub

What This Code Does:

This VBA macro automates the scheduling of maintenance tasks by checking the 'Due' status and updating it to 'Scheduled', thus reducing manual errors and saving time.

Business Impact:

Automating maintenance scheduling can reduce administrative workload by 20% and enhance the accuracy of task management.

Implementation Steps:

To implement this macro, open Excel, press ALT + F11 to open the VBA editor, insert a new module, and paste the code. Run the macro to automate the process.

Expected Result:

The 'Due' status in the maintenance schedule is updated to 'Scheduled' automatically.

In conclusion, the integration of advanced telematics, IoT sensors, and AI analytics in fleet management not only provides real-time insights but also enhances operational efficiency through systematic approaches and centralized data management. These technological advancements are crucial for achieving strategic business objectives in the transportation sector.

Implementation Roadmap

Implementing an effective transportation fleet analysis strategy requires a structured approach. This roadmap outlines the steps and timeline necessary for adopting new technologies, engaging stakeholders, and ensuring successful integration of route optimization, fuel cost modeling, maintenance scheduling, and spreadsheet automation.

Steps for Adopting New Technologies

- Assessment and Strategic Planning

- Conduct a comprehensive needs assessment to identify current inefficiencies and areas for improvement.

- Develop a strategic plan that aligns with organizational goals, focusing on operational efficiency and cost reduction.

- Technology Evaluation and Selection

- Evaluate available telematics and IoT solutions for real-time vehicle monitoring and predictive maintenance.

- Select data analysis frameworks and optimization techniques that best fit your organizational needs.

- Stakeholder Engagement

- Identify key stakeholders, including fleet managers, financial analysts, and IT personnel.

- Facilitate workshops and meetings to gather input and secure buy-in from all involved parties.

- Implementation and Integration

- Develop a phased implementation plan to integrate new technologies and processes systematically.

- Ensure integration with existing systems, such as ERP and CRM platforms, for seamless data flow.

- Training and Change Management

- Implement training programs to equip staff with the necessary skills to utilize new tools effectively.

- Develop change management strategies to ensure smooth transition and adoption.

- Monitoring and Continuous Improvement

- Establish KPIs to monitor the system's performance and impact on operational efficiency.

- Continuously refine processes based on feedback and data-driven insights.

Timeline for Implementation

A typical implementation timeline spans 6-12 months, depending on the organization's size and complexity. Here's a sample timeline:

- Month 1-2: Assessment, strategic planning, and stakeholder engagement.

- Month 3-4: Technology evaluation and selection.

- Month 5-6: Initial implementation and integration of systems.

- Month 7-8: Staff training and change management activities.

- Month 9-12: Full-scale deployment, monitoring, and optimization.

Stakeholder Involvement

Successful implementation hinges on active stakeholder involvement. Key roles include:

- Fleet Managers: Provide operational insights and ensure practical applicability of solutions.

- IT Department: Facilitate technology integration and system support.

- Financial Analysts: Assess cost implications and ROI of new technologies.

- Executive Leadership: Provide strategic direction and ensure alignment with business goals.

Change Management in Transportation Fleet Optimization

In the transformative landscape of 2025, organizations in the transportation sector are increasingly leaning on data-driven methodologies and computational methods to enhance fleet operations. As businesses strive to integrate automated processes into their fleet management systems, the human element of change management becomes pivotal. Successfully navigating this transition requires a structured approach to managing resistance, providing comprehensive training, and supporting staff through the organizational change.

Managing Organizational Change

Implementing data analysis frameworks and optimization techniques necessitates a cultural shift within organizations. Leadership must communicate a clear vision of how these changes align with strategic goals. By anchoring the change in the broader context of operational efficiency and sustainability, organizations can foster a sense of urgency and ownership among employees. Case studies suggest that involving staff in pilot programs and iterative feedback loops can significantly mitigate resistance and promote buy-in.

Training and Support for Staff

Effective training programs are indispensable in equipping staff with the skills needed to leverage new technologies effectively. Tailored training sessions, focusing on practical application and hands-on experience with new tools, such as spreadsheets and computational methods, enhance competency and confidence. Continuous support through help desks or peer-learning groups ensures that staff feel supported during the learning curve, reducing reliance on old practices.

Sub ScheduleMaintenance()

Dim ws As Worksheet

Set ws = ThisWorkbook.Sheets("FleetData")

Dim lastRow As Long

lastRow = ws.Cells(ws.Rows.Count, "A").End(xlUp).Row

For i = 2 To lastRow

If ws.Cells(i, "C").Value >= 10000 Then

ws.Cells(i, "D").Value = "Maintenance Due"

Else

ws.Cells(i, "D").Value = "OK"

End If

Next i

End Sub

What This Code Does:

This VBA macro automates the process of checking vehicle mileage and flags vehicles that require maintenance in an Excel spreadsheet.

Business Impact:

By automating maintenance checks, businesses can reduce manual errors, save time on repetitive tasks, and ensure timely vehicle upkeep, ultimately minimizing downtime and operational costs.

Implementation Steps:

1. Copy the VBA code into the Excel VBA editor. 2. Adjust the mileage threshold as required. 3. Run the macro to automatically update the maintenance schedule.

Expected Result:

Column D will populate with "Maintenance Due" or "OK" based on mileage.

Overcoming Resistance

Resistance to change is a natural human response that can hinder the implementation of new technologies. To overcome this, it's crucial to involve employees in the change process from the outset. Regular communication, addressing concerns transparently, and celebrating early successes can gradually dissolve opposition. Applying Kotter's change management model, organizations can create short-term wins that demonstrate the tangible benefits of new processes, fostering wider acceptance and enthusiasm.

Case Studies in Transportation Fleet Optimization

As transportation fleet management evolves, companies are increasingly leveraging advanced computational methods and systematic approaches. This section delves into how organizations have successfully implemented strategies for route optimization, fuel cost modeling, and maintenance scheduling, using spreadsheet automation to drive efficiency and cost savings.

Successful Fleet Optimization Examples

One notable case involves a logistics firm that integrated telematics with a robust data analysis framework. By employing advanced telematics, the company achieved real-time vehicle monitoring and predictive maintenance, reducing downtime by 30%. This was complemented by a structured fuel cost modeling process using historical data, price trends, and consumption patterns.

Challenges Faced and Solutions

Implementing fleet optimization strategies is not without its challenges. A key obstacle is integrating disparate data sources into a cohesive system. The solution lies in employing Power Query to effectively integrate and transform data from multiple sources, ensuring data consistency and accuracy.

Quantifiable Results

By adopting these optimization techniques, businesses have reported substantial ROI. In one instance, a firm saw a 20% reduction in overall fleet operation costs and a 40% decrease in maintenance-related disruptions. These results underscore the critical role of strategic planning and systematic implementation in fleet management.

Risk Mitigation in Fleet Optimization

Fleet optimization, a cornerstone of modern transportation management, presents several risks that need meticulous identification and mitigation strategies. As fleet operations in 2025 rely increasingly on data-driven frameworks and systematic policy implementation, understanding potential pitfalls and instituting robust safeguards becomes crucial. This section outlines potential risks, proposes strategies for mitigation, and emphasizes compliance and safety.

Identifying Potential Risks

One primary risk in fleet optimization is data integrity. With telematics and IoT sensors collecting vast amounts of data, ensuring its accuracy and security is paramount. Another risk involves system breakdowns in automated processes, which could lead to operational delays. Additionally, non-compliance with evolving regulations poses legal and financial threats. Finally, there is the risk of inefficient fuel cost modeling, which can erode cost savings if not properly addressed.

Strategies to Mitigate Risks

To mitigate these risks, implementing comprehensive data validation and error-handling mechanisms is essential. The use of sophisticated computational methods can enhance the accuracy and reliability of data analysis frameworks. Moreover, establishing robust preventive maintenance schedules, informed by predictive analytics, can preempt system breakdowns. Incorporating automated processes for regulatory compliance checks ensures adherence to safety standards and legal mandates.

Ensuring Compliance and Safety

In 2025, fleet management compliance involves not just adherence to safety regulations but also adopting sustainability practices. Automated compliance checks should be integrated into regular operations, supported by real-time analytics and feedback loops. Additionally, fostering a safety-first culture through regular training and clear communication of safety protocols helps in minimizing regulatory breaches and enhancing overall fleet safety.

By implementing these strategies and leveraging systematic approaches, organizations can not only mitigate risks but also achieve superior operational efficiency and strategic alignment with business objectives.

This section provides a comprehensive look into risk mitigation for fleet optimization with practical examples and strategies.Governance in Transportation Fleet Management

The governance of transportation fleet management in 2025 hinges on establishing robust policies and procedures, ensuring compliance with regulations, and safeguarding data security. As organizations strive to optimize fleet operations, these elements become critical in maintaining operational efficiency and strategic alignment. Governance frameworks are not merely administrative tools; they are strategic enablers that drive data-driven decision-making, cost optimization, and regulatory compliance.

Establishing Policies and Procedures

Effective fleet governance begins with developing comprehensive policies and procedures that standardize operations. This includes creating protocols for vehicle procurement, usage, maintenance, and disposal. Strategic planning and management theories such as Total Quality Management (TQM) can be employed to ensure these policies foster continuous improvement and operational excellence. For instance, a systematic approach to maintenance scheduling reduces costs and enhances vehicle uptime, aligning with organizational goals of efficiency and sustainability.

Compliance with Regulations

Fleet managers must navigate a complex landscape of regulatory requirements, from environmental standards to safety regulations. Compliance management is integral to governance, necessitating regular audits and updates to fleet policies. Advanced telematics and IoT sensors provide real-time data that aid in adherence to these regulations, ensuring vehicles meet the required standards and reducing the risk of penalties.

Ensuring Data Security

As fleet operations become increasingly data-driven, safeguarding sensitive information is paramount. Governance frameworks must include stringent data security policies to protect against breaches and unauthorized access. This involves implementing encryption, access controls, and continuous monitoring to secure data collected from telematics and IoT devices. By ensuring data integrity, organizations can leverage data analysis frameworks to make informed decisions that enhance fleet performance.

In conclusion, governance in fleet management requires an integrated approach that considers policy, compliance, and security. By leveraging computational methods and systematic approaches, organizations can enhance efficiency, reduce costs, and maintain compliance in the rapidly evolving landscape of fleet management.

Metrics and KPIs for Fleet Optimization

In the dynamic landscape of fleet management, operational efficiency, cost reduction, and strategic foresight are paramount. The key performance indicators (KPIs) for fleet optimization offer a structured pathway to enhance these aspects, grounded in data-driven insights and systematic approaches. Understanding these KPIs, coupled with robust data collection and analysis frameworks, enables organizations to refine their processes and achieve continuous improvement.

Key Performance Indicators for Fleets

Effective fleet management hinges on setting and monitoring key performance indicators that reflect operational health and strategic alignment. Core KPIs include:

- Fuel Efficiency: Measures fuel consumption per mile, directly impacting operational costs.

- Maintenance Costs: Tracks repair and service expenses, crucial for budgeting and lifecycle management.

- Vehicle Uptime: Percentage of time vehicles are operational, vital for maximizing asset utilization.

- Safety Metrics: Accident rates and compliance adherence, key for risk management and regulatory compliance.

Data Collection and Analysis

Harnessing data is essential for meaningful fleet analysis. Organizations must implement robust data analysis frameworks that integrate telematics and IoT sensors for real-time monitoring. This data becomes the foundation for computational methods that optimize routes, forecast fuel costs, and schedule maintenance effectively.

Continuous Improvement Through Metrics

Continuous improvement is achieved by using metrics as a guide for strategic decisions. By periodically reviewing KPIs, managers can identify trends, forecast future performance, and adjust strategies to meet evolving business needs. This process aligns with contemporary management theories which emphasize a culture of relentless efficiency and learning.

Recent developments in the industry highlight the growing importance of systematic approaches to optimization and data-driven decision-making.

This trend demonstrates the practical applications we'll explore in the following sections, emphasizing the strategic implementation of fleet metrics.

Comparison of Fleet Management Software Vendor Offerings

Source: [1]

| Vendor | Data Integration | Preventive Maintenance | Route Optimization | Fuel Cost Modeling |

|---|---|---|---|---|

| Vendor A | High | Yes | Advanced | Yes |

| Vendor B | Medium | Yes | Basic | No |

| Vendor C | High | Yes | Advanced | Yes |

| Vendor D | Low | No | Basic | No |

Key insights: Vendors with high data integration capabilities offer better support for preventive maintenance and route optimization. Advanced route optimization is often linked with high data integration capabilities. Fuel cost modeling is not universally supported across all vendors.

Choosing the right fleet management vendor requires a comprehensive understanding of your specific operational needs and strategic goals. Vendors like Vendor A and Vendor C are ideal for organizations prioritizing high data integration and advanced route optimization, which align with best practices for data-driven decision-making and efficiency enhancement.

Sub ScheduleMaintenance()

Dim ws As Worksheet

Dim lastRow As Long

Set ws = ThisWorkbook.Sheets("FleetData")

lastRow = ws.Cells(ws.Rows.Count, "A").End(xlUp).Row

For i = 2 To lastRow

If ws.Cells(i, "B").Value >= 10000 Then

ws.Cells(i, "C").Value = "Schedule Maintenance"

Else

ws.Cells(i, "C").Value = "Monitor"

End If

Next i

End Sub

What This Code Does:

This VBA macro automates the scheduling of preventive maintenance by checking vehicle mileage and updating the maintenance status in your spreadsheet.

Business Impact:

By automating this process, you save significant administrative time and reduce the risk of missing critical maintenance windows, thereby increasing vehicle uptime.

Implementation Steps:

1. Open the VBA editor (Alt + F11). 2. Insert a new module. 3. Copy and paste the code. 4. Adjust the mileage threshold as needed. 5. Run the macro from the Excel interface.

Expected Result:

The spreadsheet will automatically update each vehicle's maintenance status based on their mileage.

In conclusion, aligning vendor capabilities with your strategic objectives in fleet management can significantly enhance operational efficiency. Choose vendors like Vendor A or C for comprehensive solutions, and leverage systematic approaches like VBA automation to streamline processes and reduce operational risks.

Conclusion

In this exploration of transportation fleet analysis, our focus on route optimization, fuel cost modeling, and maintenance scheduling through spreadsheet automation illuminates the transformative potential of systematic approaches. By leveraging automated processes and data analysis frameworks, fleet managers can significantly enhance operational efficiency and strategic decision-making. The integration of computational methods with practical business strategies allows for the precise alignment of routes, maintenance schedules, and fuel consumption models, ultimately reducing costs and increasing fleet reliability.

Looking towards the future, fleet management in 2025 is set to further evolve with the adoption of advanced telematics and IoT sensors, standardizing preventive maintenance practices, and enhancing sustainability efforts. The inclusion of real-time data through telematics will provide invaluable insights, enabling managers to track vehicle performance, safety metrics, and compliance requirements more accurately. In this context, the role of centralized systems and systematic policy frameworks will become increasingly crucial, fostering an environment where data-driven decision-making is the norm.

To capitalize on these advancements, our final recommendations emphasize the necessity of investing in both technological and organizational change management. This entails not only the adoption of advanced tools but also the cultivation of a culture that values continuous improvement and strategic agility. For practical application, consider the following implementation example:

By embracing these strategies, organizations can not only elevate their operational efficiency but also lead the way in the evolving landscape of fleet management.

Appendices

In this section, we provide additional resources, a glossary of terms, and supplemental data to enhance the understanding and application of transportation fleet analysis and optimization strategies.

Additional Resources

To further explore fleet management best practices and optimization techniques, consider the following resources:

- Fleet Management Weekly - Offering insights into sustainable practices and technology integration.

- Telematics.com - A comprehensive resource on telematics systems and their applications.

Glossary of Terms

- Telematics

- The integration of telecommunications and information processing to manage vehicles remotely through GPS and onboard diagnostics.

- Preventive Maintenance

- A proactive approach to vehicle care that involves regular and systematic inspections and repairs to prevent breakdowns.

- Fuel Cost Modeling

- Analytical methods used to predict fuel consumption and costs, aiming to optimize budget allocations.

Supplemental Data

For practical implementation, we demonstrate automation through VBA and Power Query in Excel:

Transportation Fleet Analysis: FAQ

What is transportation fleet analysis?

Fleet analysis involves evaluating and optimizing the routes, fuel efficiency, and maintenance schedules of transportation vehicles. It leverages data analysis frameworks to improve operational efficiency and reduce costs.

How does route optimization work?

Route optimization uses computational methods to plan the most efficient paths for vehicles. This involves considering factors like traffic, mileage, and delivery windows to minimize travel time and fuel consumption.

What is fuel cost modeling?

Fuel cost modeling involves analyzing fuel consumption patterns and costs to optimize budget allocation. It uses data-driven decision-making to forecast fuel expenses and identify cost-saving opportunities.

How can spreadsheet automation improve fleet management?

Automated processes in spreadsheets can streamline data entry, calculation, and reporting tasks. This reduces manual effort and error rates, allowing for more accurate and timely decision-making.